Cable production is a high-load, precision-driven industry where equipment runs long hours under demanding conditions. Choosing the right Electric Motors for Cable Manufacturing in South Africa directly affects production speed, product quality, and long-term operating costs. From extrusion lines to stranding machines, every stage of cable manufacturing depends on motors that deliver steady torque, accurate speed control, and continuous-duty reliability.

South African cable manufacturers operating in power, telecom, and industrial sectors need motor solutions that handle constant mechanical stress while maintaining process accuracy. This is where specialized industrial electric motors South Africa facilities become essential.

Why Electric Motors Matter in Cable Production

Cable manufacturing is not a simple start-and-stop process. It requires smooth, synchronized motion across multiple machines. Electric motors for cable production must provide consistent torque, rapid response to load changes, and compatibility with variable speed control systems.

In many plants, motors operate 24/7. Downtime means lost material, missed delivery schedules, and higher maintenance costs. This makes high-performance industrial motors a core part of any reliable cable plant setup.

Electric Motors for Cable Manufacturing in South Africa: Key Applications

Different stages of production place different demands on cable manufacturing motors. Understanding these requirements helps manufacturers select the right motor type and configuration.

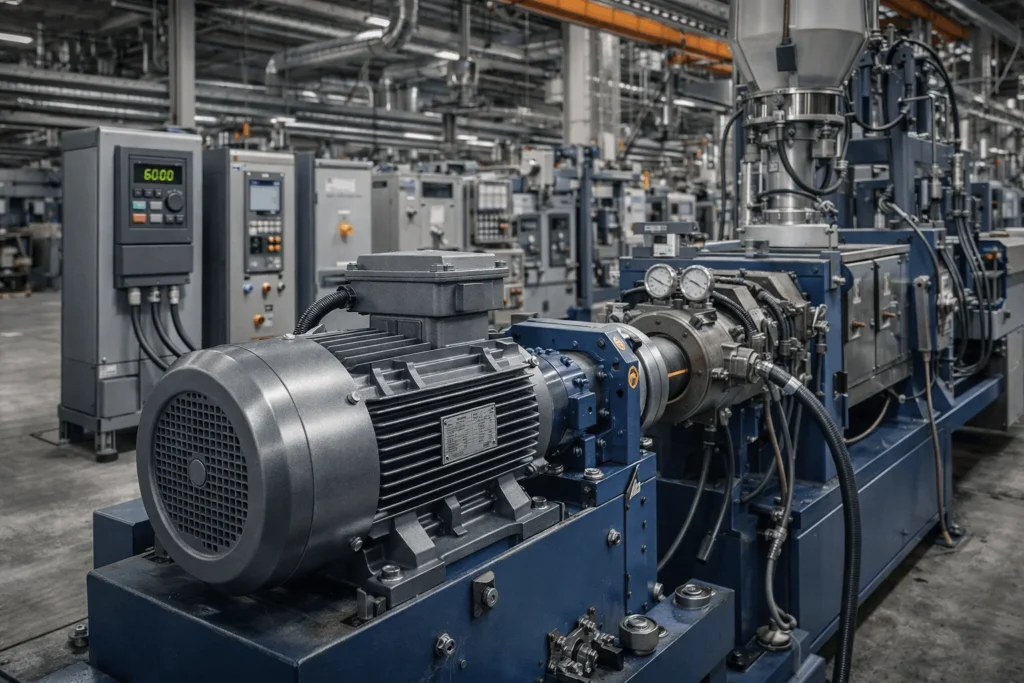

1.) Extruder Drives

Extruders require high-torque motors with inverter-duty capability. Speed must be adjusted precisely to control insulation thickness for PVC or XLPE cables. These systems typically use Variable Frequency Drives (VFDs) to maintain stable output while adapting to load changes.

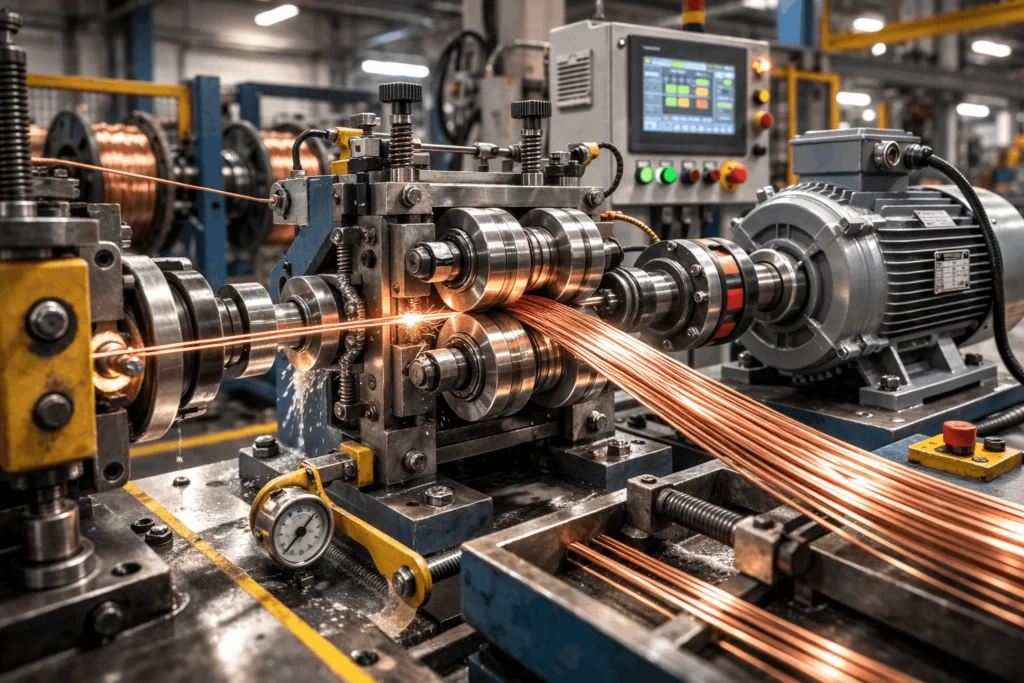

2.) Wire Drawing and Stranding

Wire drawing reduces conductor diameter, while stranding combines multiple wires. Both processes demand accurate torque control and speed synchronization. Any variation can cause wire breakage, leading to material waste and production delays. Motors used here must respond instantly and operate smoothly under fluctuating tension.

3.) Haul-Off / Caterpillar Units

These units pull finished cable through the line. Motors must deliver constant traction and uniform speed. Geared configurations are common in these cable plant motor solutions, providing the torque required to move heavy cable lengths without slipping or stretching.

4.) Take-Up and Pay-Off Systems

As reel diameter changes during winding or unwinding, motor speed must automatically adjust to maintain constant tension. VFD-controlled systems are standard here, helping prevent deformation or damage to the cable.

Motor Specifications for Cable Manufacturing

When selecting Electric Motors for Cable Manufacturing in South Africa, certain specifications are critical for long-term performance.

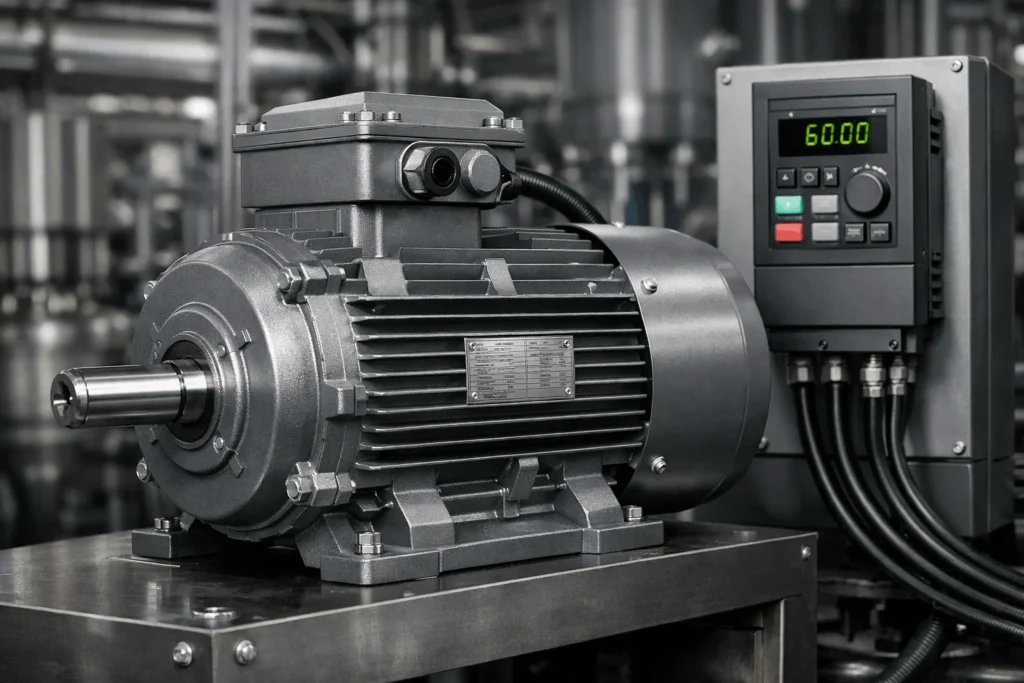

1.) Motor Type

Three-phase AC induction motors are the industry standard. Both low-tension (LT) and high-tension (HT) variants are used depending on plant design and load requirements. Many facilities also integrate AC/DC motors for manufacturing where legacy systems or specialized processes require them.

2.) Power Ratings

Motor sizes vary widely. Smaller components may use fractional horsepower motors, while large extruders can demand high-kilowatt ratings to handle continuous heavy-duty loads.

3.) Protection & Durability

Cable plants often operate in dusty, high-temperature environments. Motors with IP55 or higher protection ratings help prevent ingress of dust and contaminants, extending equipment life and reducing failures.

4.) Speed & Tension Control

Variable Frequency Drives are essential. They allow smooth acceleration, precise speed regulation, and accurate tension control across multiple synchronized machines.

Energy Efficiency and Long-Term Savings

Energy costs are a major factor in cable manufacturing. Modern energy-efficient industrial motors, especially IE3 and IE4 rated models, help reduce power consumption without sacrificing performance. Over time, these motors lower operational expenses and support more sustainable production practices.

Upgrading older motors to higher-efficiency models can significantly cut electricity usage, particularly in continuously running equipment like extruders and haul-off systems.

Common Cable Machinery That Depends on Reliable Motors

A wide range of equipment in cable factories depends on specialised motor systems, including:

- PVC and XLPE cable extruders

- Wire enamelling machines

- Cable twisting and armouring machines

- Caterpillar haul-off machines

Each of these applications requires durable, precisely controlled motor systems designed specifically for heavy industrial use.

Maintenance and Operational Reliability

Consistent performance also depends on proper motor maintenance for cable factories. Routine inspections, alignment checks, and condition monitoring help identify issues before they lead to costly downtime. Motors built for inverter duty and continuous operation reduce wear, especially in high-cycle environments.

Working with experienced industrial motor suppliers South Africa manufacturers trust can make maintenance planning easier through access to spare parts, technical guidance, and fast replacement options.

Why Partner with the Right Motor Supplier

Selecting the correct motor is not only about specifications. It also involves application knowledge, technical compatibility, and long-term support. Alliance Industrial Products motors are designed for heavy industrial applications and include IE3 and IE4 efficiency options suitable for modern cable plants. Direct supply and technical coordination help manufacturers match motor performance with real production demands.

Conclusion

Reliable motor performance is at the core of safe, efficient, and consistent cable production. From extruders to haul-off units, every stage depends on durable, precisely controlled drive systems. Investing in the right Electric Motors for Cable Manufacturing in South Africa helps reduce downtime, improve product quality, and lower long-term operating costs while supporting continuous industrial output.