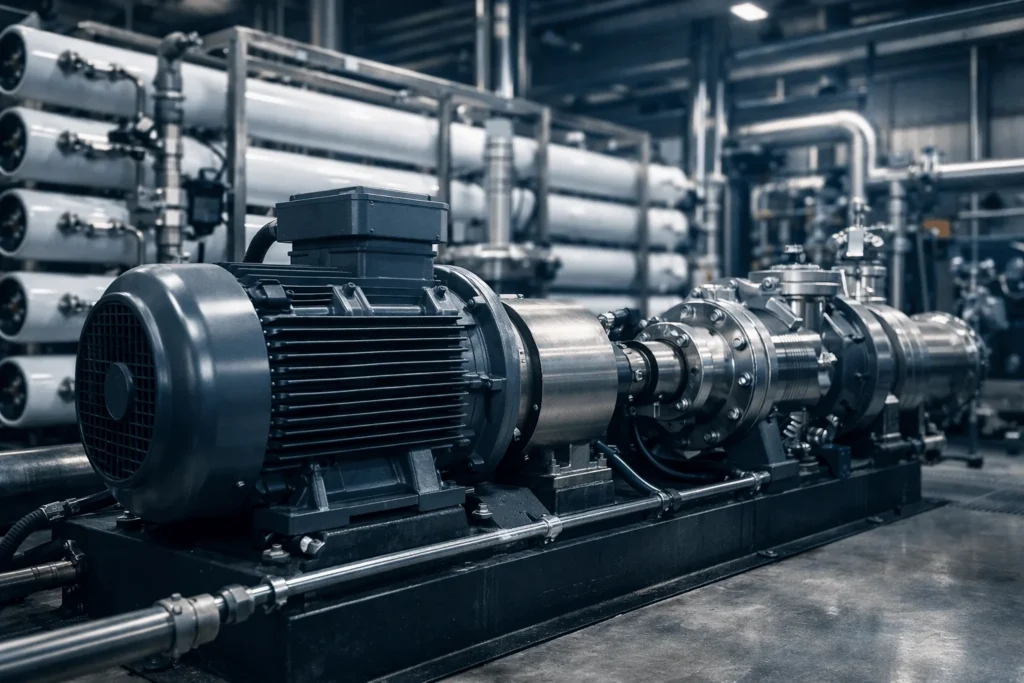

Qatar depends heavily on desalination for its freshwater supply. Since natural water sources are limited, plants must run every day without long stops. At the center of these facilities are industrial electric motors for desalination plants. These motors drive pumps, compressors, and other key systems that move and treat seawater.

If motors fail, water production drops. So, motor selection directly affects plant reliability and energy use.

Why electrical component for desalination plant market face tough conditions

Desalination plants work in hot and salty environments. Air near the coast carries salt, moisture, and fine particles. Over time, these conditions can damage equipment.

That is why heavy duty industrial motors water plants rely on must handle:

- Long running hours without frequent shutdowns

- High ambient temperatures

- Humid and salty air

- Heavy mechanical loads from large pumps

Strong insulation, sealed housings, and proper cooling help motors survive in these settings.

Seawater Desalination Motor Applications Across the Plant

Many systems inside a desalination plant need motors. Each one plays a different role in the water treatment process. These seawater desalination motor applications demand stable speed and torque.

Key motor driven equipment includes:

- Seawater intake pumps

- High pressure pumps

- Booster pumps between treatment stages

- Chemical dosing units

- Brine discharge pumps

Some motors run at constant speed. Others adjust speed based on plant demand. Both types must stay reliable during long shifts.

Read More: How Alliance Industrial Gearboxes Help the Food and Beverage Industry

Pump Motors for Desalination Plants and Pressure Control

Pumps move water through every stage of desalination. Because of this, motors for desalination plants must deliver smooth and steady performance.

Unstable motor speed can cause pressure swings. That can affect membranes and lower system efficiency. Well matched motors help maintain:

- Stable flow rates

- Consistent discharge pressure

- Reduced vibration in piping systems

Lower vibration also means less wear on bearings and seals.

Read More: Valve Selection Simplified: The Criteria to Follow

Electric Motors for Reverse Osmosis Systems

Reverse osmosis is the core stage of most modern plants. This process uses high pressure to push seawater through membranes.

So, electric motors for reverse osmosis systems must handle heavy loads and long duty cycles. These motors often work with variable frequency drives.

This setup helps by:

- Reducing stress during startup

- Allowing speed control based on demand

- Improving overall energy use

Better motor control also protects expensive membrane systems.

Corrosion Resistant Electric Motors Desalination Plants Need

Salt is one of the biggest threats in these facilities. It can attack metal surfaces and reduce motor life.

For this reason, corrosion resistant electric motors desalination plants install usually include:

- Special protective coatings

- Stainless steel external parts

- Improved sealing against moisture

- Enclosures designed for coastal conditions

These features reduce maintenance needs and extend equipment life.

High Efficiency Motors for Desalination and Energy Savings

Energy costs form a large part of desalination expenses. So, high efficiency motors for desalination help plants control operating budgets.

Efficient motors:

- Convert more electrical power into useful output

- Produce less heat

- Reduce strain on cooling systems

- Lower overall power consumption

Over time, this leads to noticeable savings in large facilities.

How Motor Types Match Plant Functions

Here is a simple overview of where different motors are used:

| Plant Section | Motor Role | Key Requirement |

| Seawater Intake | Drives large intake pumps | High reliability |

| Reverse Osmosis | Runs high pressure pumps | High torque and control |

| Chemical Dosing | Powers mixers and pumps | Precise speed control |

| Brine Discharge | Operates discharge pumps | Corrosion resistance |

| Post Treatment | Supports conditioning systems | Energy efficiency |

Many of these systems also fall under industrial motors for water treatment plants, since desalination includes several treatment stages.

Conclusion: Industrial Electric Motors for Desalination Plants Keep Water Flowing

Reliable industrial electric motors for desalination plants support every step of water production in Qatar. From seawater intake to final treatment, motors keep processes moving.

By using corrosion resistant designs, high efficiency models, and motors suited for specific seawater desalination motor applications, plants can improve uptime and manage energy costs.

In facilities that run day and night, motor performance is not just a technical detail. It is a core part of keeping fresh water available every single day.